Car Lamp Hot Plate Welding Machine

NC-S Series/NC-E Series

● Automatic Cleaning:

Features self-cleaning molds to ensure reliable welding of automotive lamp plastic housings.

●Material Versatility:

Handles multiple materials including PP, PC, and PMMA for car lamp welding.

● Superior Strength:

Creates welds stronger than the original material in automotive light housings.

● Depth Control:

Maintains precise hot melt welding depth across all surfaces.

● User-Friendly:

Car lamp hot plate welding machine features PLC controls with an intuitive interface for simple operation.

● Conclusion:

Hot plate welding machines are essential in automotive lamp manufacturing. Their high efficiency, stability, precision, reliability, wide applicability, and excellent sealing properties make them indispensable for automotive lighting production.

Request for Quote- Features |

- Cases & Parameters |

- Certification |

- Copperation Steps |

- Advantages |

- Packaging |

- Solution |

- Appilications |

- Reviews

Car Lamp Hot Plate Welder Features

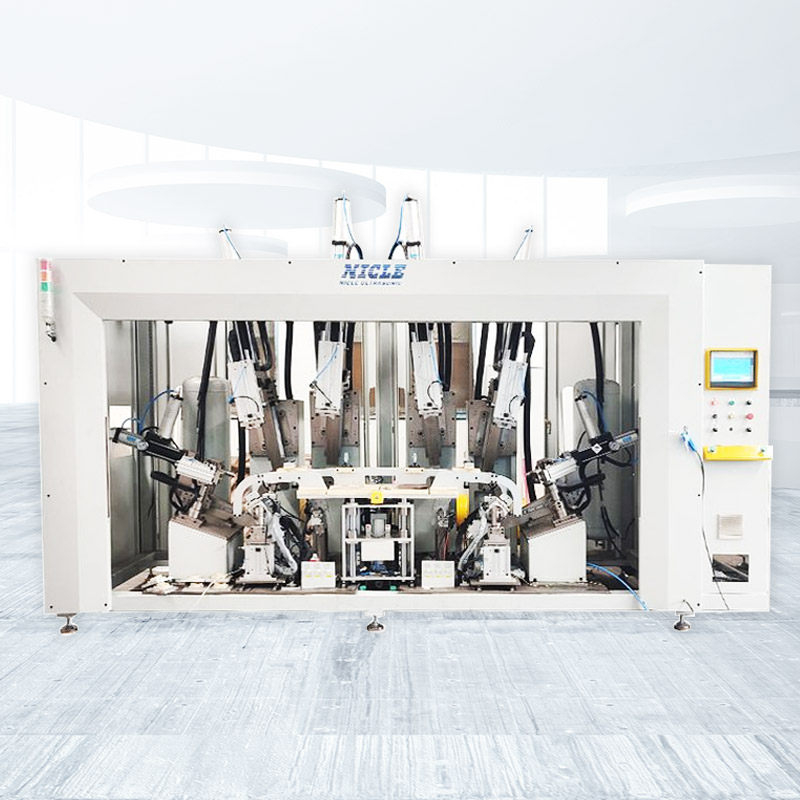

The automotive lamp hot plate welding machine offers a versatile and efficient way to secure lamp panels to housings—ideal for automotive headlights, turn signals, brake lights, taillights, and fog lights.

The automotive lamp hot plate welding machine uses a temperature-controlled heating device to join plastic components. The heating device sits between two plastic parts; when the workpiece contacts it, the plastic melts to create a bond. The car lamp hot plate welding machine features an automatic cleaning system where a lifting cylinder uses a cloth to clean the hot mold surface during operation. Its depth control technology ensures precise welding on both flat and curved surfaces. A PLC system controls the entire process, offering easy parameter adjustments to optimize production efficiency while maintaining consistent temperatures across the control board.

Hot plate welding produces strong, debris-free bonds in automotive lamps. This method works particularly well for lamp assemblies that need to balance aesthetic requirements with complex structures. The Dizo automotive lamp hot plate welding machine works with PP, PC, and PMMA, etc.

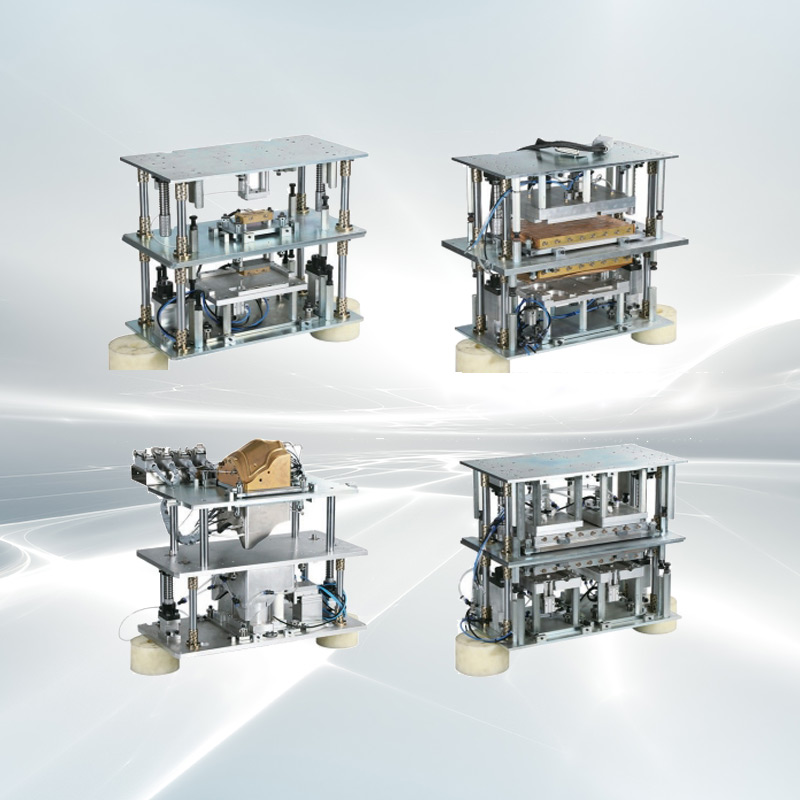

Car Lamp Welding Cases

Car Lamp Welder Parameters

| Type | Standard Pneumatic Car Lamp Hot Plate Welder | Servo Car Lamp Hot Plate Welder | Quick-Change Servo Car Lamp Hot Plate Welder |

|---|---|---|---|

| Model | DZ-350 | DZ-800S | DZ-1000SF |

| Equipment Dimension | W1400*L1500*H2100mm | W2000*L2200*H2600mm | W2200*L2400*H2800mm |

| Voltage | 380V | 380VAC | 380VAC |

| Maximum Welding Size | 350*200mm | 800*450mm | 1000*600mm |

We are Internationally Certified

Our car lamp hot plate welding machines for automotive headlights, turn signals, brake lights, taillights, and fog lights are certificated with CE,ISO and ROSH. They all meet international standards.

Purchasing Guide: Car Lamp Hot Plate Welding Machines

We provide comprehensive plastic welding solutions for automotive headlights, turn signals, brake lights, taillights, and fog lights. Follow these steps to complete the process:

-

STEP 1

Sample Evaluation

Review automotive lamp sample requirements and technical specifications.

-

STEP 2

Feasibility Study

Analyze the feasibility of the welding techniques for the car lamp application.

-

STEP 3

Prototype Development

Create and test prototypes based on the evaluated automotive lamp samples.

-

STEP 4

Customer Approval

Present the prototype to gather feedback and secure customer approval.

-

STEP 5

Quotation

Issue a detailed quotation for the selected hot melt welding machine.

-

STEP 6

Order Confirmation

Finalize the order and confirm all specifications.

-

STEP 7

Manufacturing Process

Manufacture the hot melt welding machine according to the confirmed order details.

-

STEP 8

Quality Assurance

Conduct thorough quality checks to ensure the machine meets all standards.

-

STEP 9

Delivery and Installation

Deliver the welding machine and complete installation at the customer's site.

-

STEP 10

Training and Support

Provide training and ongoing support to ensure smooth operation of the equipment.

Custom Dizo Car Lamp Hot Plate Welder Advantages

Works with Any Size

Hot plate welding fits all sizes of car lamp plastic parts without area limits.

Any Surface Works

Car lamp hot plate welders can weld any type of surface easily.

Strong and Adaptable

Can be adjusted to different shapes while staying strong.

Customized for Each Material

Suit different materials, keeping it precise and easy to control.

Packaging for Car Lamp Hot Plate Welder

Hot Plate Welding Solutions in Plastic Welding Industry

Hot plate welding machines are trusted solutions in the plastic welding industry, creating strong and reliable bonds for diverse applications. These machines excel at complex welding tasks and serve multiple industries—automotive manufacturing, household appliances, environmental filtration products, electronics, plastic toys, audiovisual products, and packaging.

Dizo's hot plate welding machines incorporate advanced systems engineered for durability, efficiency, and seamless production line integration. They deliver superior welding strength and consistent quality across both flat and curved surfaces, providing dependable results every time.

These hot melt welding solutions combine precision with versatility, creating perfect welds for plastic components made from thermoplastic materials such as PP, PE, ASA, ABS, PC, PET, PMMA, PVDF, PVC, etc.

Learn More

Other Hot Plate Welding Applications

Hot plate welding works best with thermoplastics (PP, PE, ASA, ABS, PC, PET, PMMA, PVDF, PVC, etc.) for large complex pieces, offering strong joints, excellent sealing, thick-wall compatibility, and clean welds.

Used across industries, it's vital in automotive for waterproof irregular parts, appliance manufacturing for housings, storage container production, and medical equipment assembly.

Customer Reviews

Quote Now

Quote Now